SiTime launched its Epoch Platform of MEMS OCXOs, delivering 2× better performance and 3× lower power for data centers and network equipment.

SiTime Corp. recently unveiled its Epoch Platform of MEMS-based, oven-controlled oscillators (OCXOs). The new precision timing platform, designed for complex timing issues in data center and network infrastructure equipment, is touted as the technology to “disrupt 100-year-old quartz-based technology.”

The Epoch Platform, leveraging a systems-based development approach that combines MEMS, analog, packaging and algorithms, provides an ultra-stable clock for data center and network infrastructure equipment, valued at a $2 billion served addressable market (SAM) in the next decade. Over time, the Epoch technology is expected to extend into other high-growth electronics markets, such as aerospace and defense and industrial controls.

“We are now in the intelligent connected electronics era,” said Piyush Sevalia, SiTime’s executive VP, marketing. “Modern electronic devices are always connected, and they are fast and easy to use. They are also making decisions and getting smarter.”

For this to work, ultra-fast networks that never fail are needed, he added. “We need processing in the core, in the edge and local, and then we need data to be synchronized so this is fundamentally different than what it was a decade or two decades ago.”

With precision timing, it enables electronic products that are smarter, faster and safer by delivering precise and reliable clock signals that always work in every environment, Sevalia said.

In network infrastructure, every infrastructure load must be time-synchronized, and this synchronization only gets more stringent with newer standards, he said. “For example, in a 4G network the time accuracy between any two nodes in the network is 1.5 µs and in a 5G network, the time accuracy is 130 ns.”

In addition, the equipment also often operates in harsh environments, which can impact the performance of the network. One of the challenges in the industry today is that legacy quartz OCXOs are inherently prone to performance degradation due to environmental stressors such as temperature changes and vibration.

There are challenges that network equipment vendors face with quartz OCXOs such as in fan-cooled routers where they are susceptible to thermal gradients inside the system and require workarounds to keep the clock stable, Sevalia explained.

In addition, some equipment vendors have been using two quartz OXCOs for redundancy, so if one fails, they can automatically fall back to another one, he said. “In our case, we are offering better reliability due to the silicon MEMS technology and therefore they don’t need to use two OCXOs.”

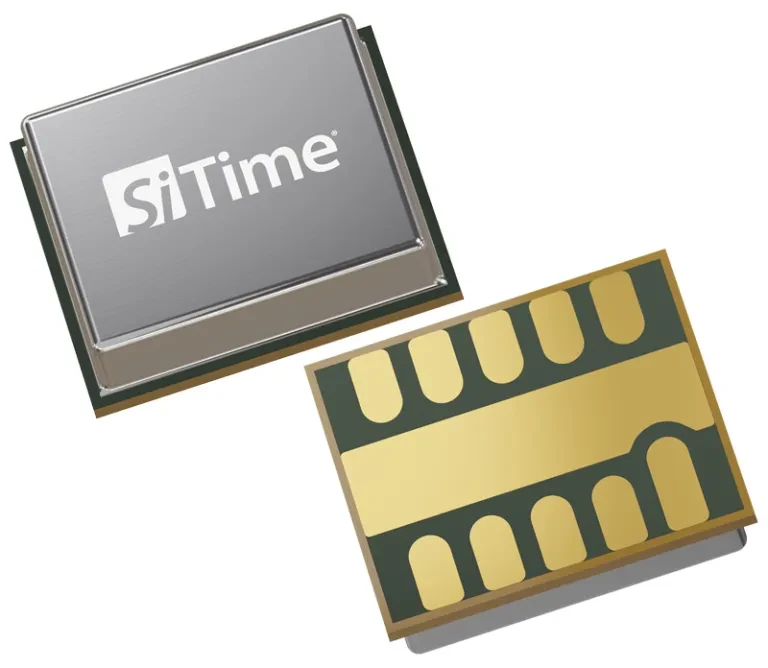

SiTime's Epoch Platform of MEMS OCXOs.

SiTime said the Epoch platform “sets a new bar in performance and reliability” with 2× better performance (holdover), 9× smaller size (9 × 7 × 3.73 mm) and 3× lower power (420 mW) in applications such as data-center switches and routers, 5G base stations and core infrastructure.

It also delivers 2× faster time to stability (60 seconds), 3× lower aging (±0.08 ppb/day) and 3× better ADEV under airflow (5e-12 at 10 seconds averaging time). These devices are available with any frequency between 10 and 220 MHz and are programmable up to six decimal places of accuracy and ±1, ±3, ±5 ppb frequency stability over temperature. Operating supply voltages are 2.5 V, 2.8 V and 3.3 V. The highest operating temperature range is -40°C to 95°C. Digital control is via I2C and SPI interfaces.

In SiTime tests that compare the MEMS OCXO to a quartz OCXO, both with a stability of ±1 ppb, the MEMS OCXO offers better performance on a number of different parameters. Compared to a quartz OCXO, the MEMS OCXO’s warm-up time is a minute versus five minutes, Allan deviation (ADVE) [or short-term frequency stability] under airflow is almost a half an order of magnitude better, part-to-part deviation is 10× lower and it has 1/4 the power consumption and 1/8 the size, Sevalia said.

Holdover translates into higher reliability

One of the key performance features of the Epoch platform is the 2× longer holdover even during environmental stressors, compared with other solutions, which ensures higher reliability and continuous network operations.

As noted by Sevalia, all nodes in a 5G network must be synchronized within hundreds of nanoseconds, which is 10× more stringent than 4G, and it must be maintained even despite network outages, which is why the Epoch’s holdover performance is a big deal.

Synchronized networks use multiple, redundant timing devices to ensure continuous operation. One of these is an ultra-stable local oscillator, typically an OCXO. These devices “holdover” the networks to ensure continued operation when other timing sources are impacted.

OCXOs are used as local time sources across the network infrastructure in case there is a disruption in the GNSS time or network time due to a number of reasons such as weather conditions, jamming or spoofing. To ensure service continuity, OCXOs are used to holdover the network until the more accurate time comes into play.

The Epoch Platform offers eight hours of holdover, up to 12 hours with aging compensation.

“A long time ago carriers used to have a holdover time of 72 hours, but there was no performance reason for a holdover time of 72 hours,” Sevalia said. “If some network equipment went down, nobody would go out over the weekend and actually fix the box or replace it, so that’s why they had a holdover requirement of 72 hours.

“Today, you can’t get a 72-hour holdover time at the speed at which these networks are transmitting and so now carriers are asking for 8 hours, 12 hours, 16 hours or 24 hours, depending on what the accuracy levels are, so this spec becomes very crucial in the network,” he added.

Engineering samples of the SiT58xx Epoch Platform are available now for qualified customers. General samples will be available in October 2023, followed by volume production in early 2024.

Diodes Inc. has launched two new families of monolithic, unipolar Hall-effect switches for proximity sensing in battery-powered applications. The AH138x/AH139x Hall-effect switches offer an ultra-low 1.1-µA supply current at 1.85 V and 1.6 µA at 1.6 V to 5.5 V. Battery-powered applications include smartphones, laptops, and wearables. They also can be used in domestic appliances, game consoles and industrial hardware.

Diodes Inc. has launched two new families of monolithic, unipolar Hall-effect switches for proximity sensing in battery-powered applications. The AH138x/AH139x Hall-effect switches offer an ultra-low 1.1-µA supply current at 1.85 V and 1.6 µA at 1.6 V to 5.5 V. Battery-powered applications include smartphones, laptops, and wearables. They also can be used in domestic appliances, game consoles and industrial hardware.