Belden Inc. has introduced four new products and updates to its connector, cable management and network management suite that are designed to improve network connectivity and uptime in rugged environments. These include expansions to the OptiTuff line and PROVIZE network planning, commissioning and management suite as well as a new connector and I/O module from Lumberg Automation.

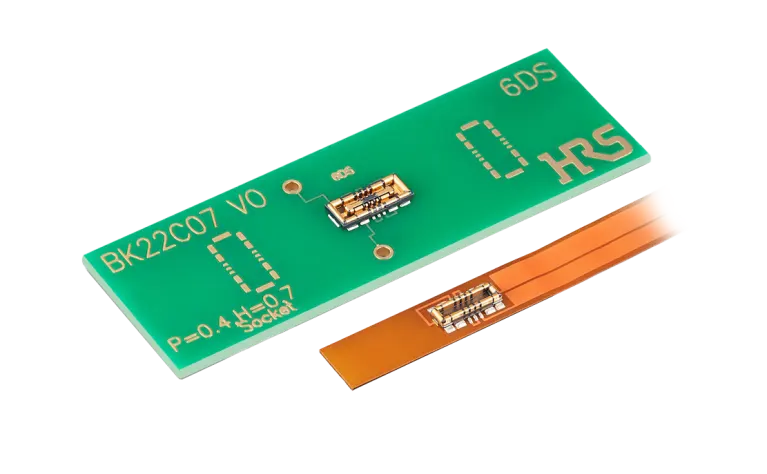

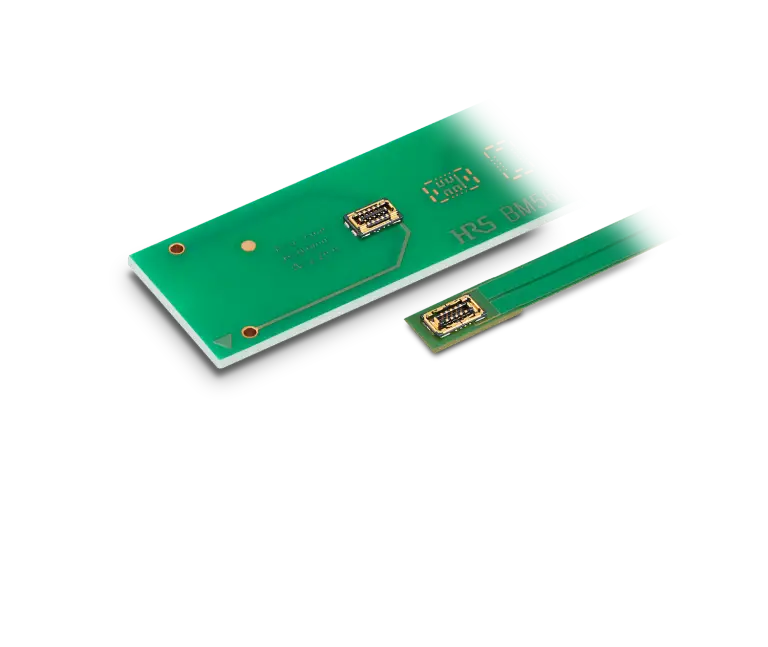

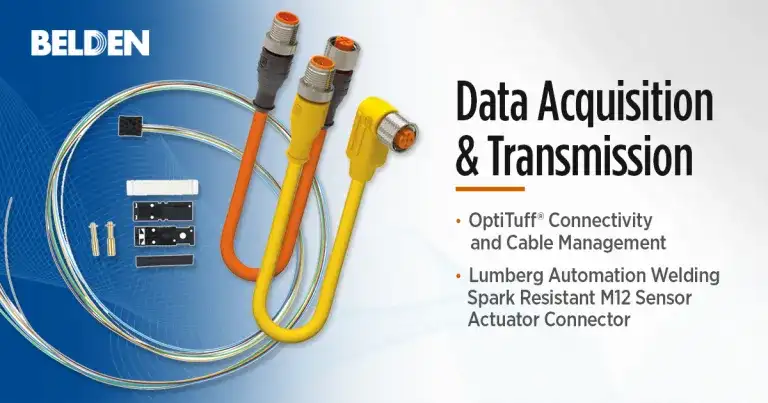

Data acquisition and transmission interconnects

The OptiTuff connectivity and cable management options add support for new field-termination connectivity for the mini fiber cables. The line provides easy installation and compatibility with the FX Fusion splice-on connector and FX ECX patch panel system.

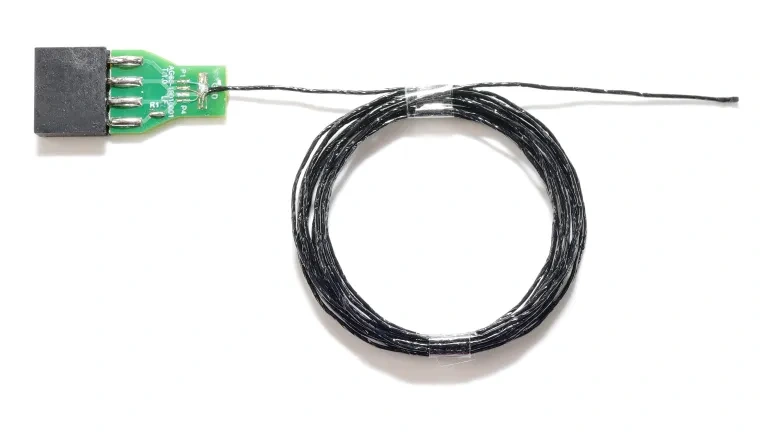

The new Lumberg Automation M12 circular connector automotive line can withstand harsh environments, thanks to its new polyurethane (PUR) construction, which prevents damage caused by welding sparks, crushing and shearing. It is reported to tolerate higher heat and pressure than standard PVC or silicone connectors.

Earlier this year, Belden also added a 4-channel SMPTE cable in riser and plenum versions. This multi-channel hybrid cable allows four cameras to be connected in a single installed cable. Also added to the portfolio are VFD cable glands that allow explosion-proof or general-purpose ingress of VFD cables into enclosures and devices. They can be used for all types of unarmored tray cables, flexible cables and cords even in harsh industrial environments.

Data orchestration and management solutions

The PROVIZE network planning, commissioning and management suite was updated to simplify MRP configuration for redundant ring topologies to prevent network disruptions. It also includes improvements to the user interface and enhanced integration that enables users to move between the PROVIZE Planner and Explorer easier.

Both Explorer and Planner were recently added to the PROVIZE portfolio. The Explorer enables device commissioning by assigning management IP addresses and credentials. The Planner allows users to collect requirements, build and validate intent-based networks and automatically create and export bills of materials listing recommended equipment.

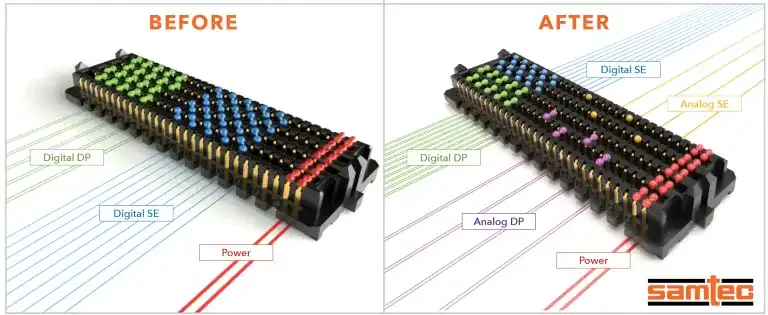

The new Lumberg Automation LioN-X digital I/O modules offer integration in PLC and cloud environments, making them a good fit for almost all industrial applications, said Belden. They provide fast configuration, data transfer and data security for automation applications using digital sensors and actuators.